Polyvinyl chloride (PVC) was one of the first plastics discovered and is also one of the most extensively used. It is derived from salt (57%) and oil or gas (43%). It is the world’s third-most widely produced synthetic plastic polymer, after polyethylene and polypropylene. PVC comes in two basic forms: rigid (sometimes abbreviated as RPVC) and flexible.

PVC’s combination of properties enables it to deliver performance advantages that are hard to match. It is durable, light, strong and fire resistant, with excellent insulating properties and low permeability. By using various additives in the manufacturing process, features such as strength, rigidity, color, and transparency can be adjusted to meet specific needs.

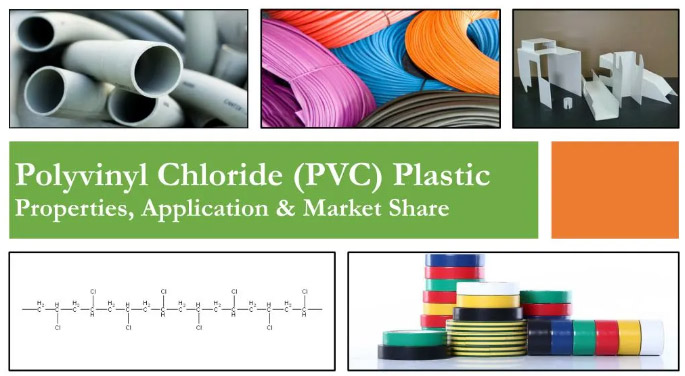

Applications

PVC is widely used in applications such as:

- Building products, including window frames and other profiles, floor and wall coverings, roofing sheets, linings for tunnels, swimming-pools and reservoirs.

- Piping, including water and sewerage pipes and fittings, and ducts for power and telecommunications.

- Coatings, including tarpaulins, rainwear and corrugated metal sheets.

- Insulation and sheathing for low voltage power supplies, telecommunications, appliances, and automotive applications.

- Packaging, pharmaceuticals, food and confectionery, water and fruit juices, labels, presentation trays.

- Automotive applications, including cables, underbody coating and interior trimmings.

- Medical products, including blood bags, transfusion tubes and surgical gloves.

- Leisure products, including garden hoses, footwear, inflatable pools, tents.