Royal Global Energy as Major supplueier of Emulsions Bitumen

Bitumen Emulsions have being developed and exponentially increased sinned they were created in 1900. Estimated presently at 20% of the global bitumen use, bitumen emulsions are basically an O/W – Oil on Water solution – A dispersion of bitumen particles on water, stabilized with the addition of surfactants – Surface active agents – or most commonly known as emulsifiers, that will permit the bitumen to be diluted in water. They are primarily used for tack coats for use in between hot mix asphalt layers and prime coats for thin hot mix surfacing layers or a chip seal pavements.

Bitumen emulsions are divided into three categories:

- Anionic with negatively charged globules

- Cationic with positively charged globules

- Non-ionic with neutral globules.

The main grades for bitumen emulsions are classified as follows:

| Anionic Emulsion Code | Cationic Emulsion Code | Setting Type |

|---|---|---|

| ARS | CRS | Rapid Setting |

| AMS | CMS | Medium Setting |

| ASS | CSS | Slow Setting |

Bitumen Emulsion is an area where technological progress is still being made to meet the requirements of pavement engineering. Anionic emulsions were first developed. They are currently less favored than the cationic emulsions, as cationic emulsions coat the aggregates more efficiently due to their positive load and have therefore better adhesion properties. Cationic Emulsion is both more favored and more widely used.

Emulsified Bitumen usually consists of bitumen droplets suspended in water. This dispersion under normal circumstances would not take place since everyone knows that oil and water don’t mix, but if an emulsifying agent is added to the water the asphalt will remain dispersed. Most emulsions are used for surface treatments. Emulsions enable much lower application temperatures to be used. Application temperatures range from 45°C to 70°C. This is much lower than the 150 to 190°C used for hot mix asphalt cements. The lower application temperatures will not damage the asphalt and are much safer for field personnel.

In the production of bitumen emulsion, water is treated with an emulsifying agent and other chemicals and is pumped to a colloid mill along with bitumen. The colloid mill breaks the bitumen up into tiny droplets. The emulsifying agent migrates to the asphalt-water interface and keeps the droplets from coalescing. The emulsion is then pumped to a storage tank.

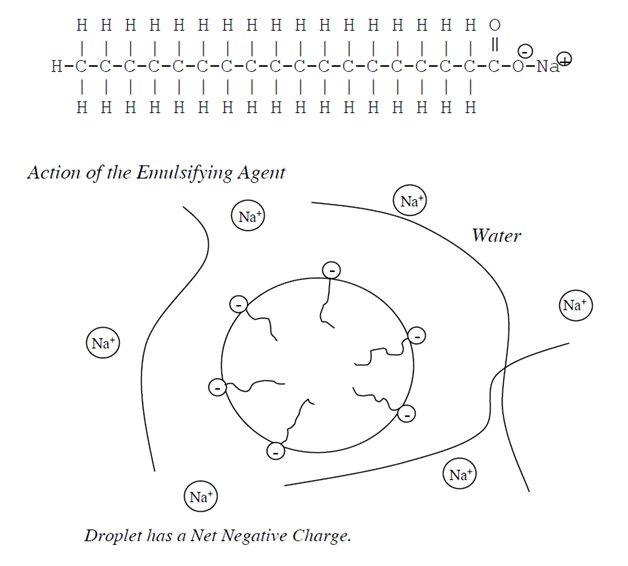

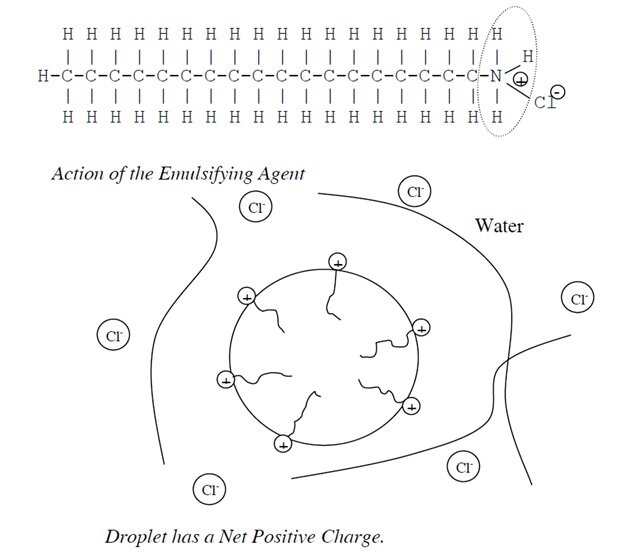

Bitumen emulsions are complicated and good chemistry is required to reach target desired emulsion properties. Variables in emulsion production include the base bitumen and the type and amount of emulsifying agent. There are two basic classifications of emulsions globally usually used, anionic bitumen emulsions and cationic bitumen emulsions. The type (chemistry) of the emulsifying agent used, determines the designation. Emulsifying agents are the chemicals used to stabilize the emulsion and keep the “billions and billions” of bitumen drops separated from one another. These compounds are large organic molecules that have two distinct parts to them. These parts are called the “head” and “tail.” The “head” portion consists of a group of atoms that chemically have positive and negative charge areas. These two charged areas give rise to the head being called polar (as in poles of a magnet). Because of this polarity, and the nature of some of the atoms in this polar head, the head is soluble in water. The tail consists of a long chain organic group that is not soluble in water but is soluble in other organic materials like oils (bitumen). Thus, an emulsifying agent is one molecule with both water-soluble and oil-soluble portions. This unique characteristic gives the chemical its emulsifying ability.

The term anionic is derived from the migration of particles of bitumen under an electric field. The droplets migrate toward the anode (positive electrode), and hence the emulsion is called anionic. In an anionic emulsion, there are “billions and billions” of bitumen droplets with emulsifying agent at the water bitumen interface. The tail portion of the emulsifying agent aligns itself in the bitumen while the positive portion of the head floats around in the water leaving the rest of the head negatively charged and at the surface of the droplet. This imparts a negative charge to all the droplets. Since negatives repel each other, all the droplets repel each other and remain as distinct bitumen drops in suspension. A typical anionic emulsifying agent is shown below along with a diagram showing the orientation of the agent at the bitumen-water interface and the negative charge imparted to each drop.

The term cationic is derived from the migration of particles of bitumen under an electric field also. The droplets migrate toward the cathode (negative electrode), and hence the emulsion is called cationic. The cationic emulsifying agent functions similarly to the anionic; the negative portion of the head floats around in the water leaving a positively charged head. This imparts a positive charge to all the droplets. Since positives repel each other, all the droplets repel each other and remain as distinct bitumen drops in suspension. A typical cationic emulsifying agent is shown below along with a diagram showing the orientation of the agent at the bitumen-water interface and the positive charge imparted to each drop.

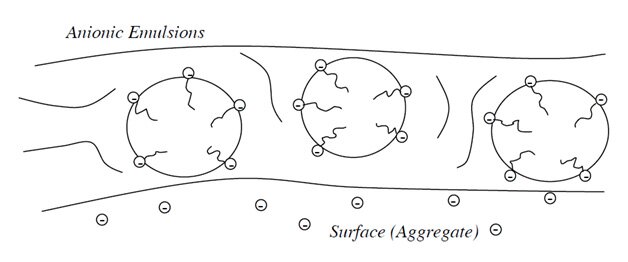

Emulsions exist for ease of application. After application the water to should evaporate and leave the asphalt cement. In a surface treatment, after emulsion and aggregate have been applied to the road surface, the emulsion should “break” leaving the asphalt cement holding the aggregate. At that point traffic may be allowed on the surface without loss of aggregate. The type of emulsion used has a large effect on the speed of the “break” of an emulsion. Almost all surfaces have a net negative charge. The strength or intensity of this negative charge may be different from material to material. Because of this phenomenon, anionic and cationic emulsions break in different ways. In an application of anionic emulsion, negatively charged drops of asphalt are applied to a negatively charged surface. All components repel each other. The only way the emulsion can break is through the loss of water by evaporation. As more and more water is lost through evaporation, the particles are forced closer and closer together until they can no longer be separated by a film of water. At this point droplets coalesce into larger and larger drops and ultimately a sheet of asphalt on the road. A depiction of the application is shown below:

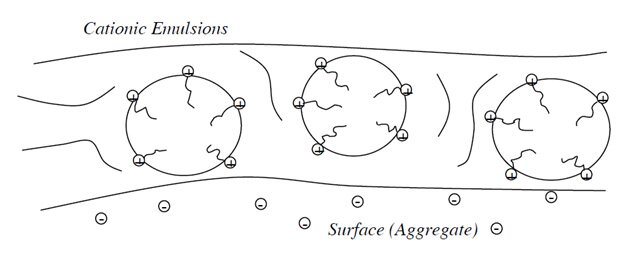

In an application of cationic emulsion, we are applying positively charged drops of bitumen to a negatively charged surface. The bitumen drops are immediately attracted to the surface and begin to break. The emulsion also loses water by evaporation. Thus the cationic emulsion has two breaking mechanisms at work and will break faster than a corresponding anionic emulsion. A depiction of the application is shown below:

The object of a surface treatment is to seal the road from moisture intrusion and provide a new skid resistant surface, but be open to traffic as soon as possible and retain aggregate. Due to the chemistry of emulsions, they may react differently in specific weather and application conditions. If you have problems in any of these areas, the problem could be because of the weather, aggregate condition or emulsion used.

In bitumen emulsions the basic bitumen has also been diluted in order to facilitate application. Hot bitumen, water and emulsifier are processed in a high-speed colloid mill that disperses the bitumen in the water. The emulsifier produces a system in which fine droplets of bitumen, of between 30% and 80% of the volume, are held in suspension. If they separate in storage, the emulsion can easily be restored by agitation.

Bitumen emulsions have a low viscosity and can be workable at ambient temperatures, which makes them ideal for use in road pavements and surfacing. This application requires controlled breaking and setting. The emulsion must not break before they are laid on the road surface but, once in place, they should break quickly so that the road can be in service again without delay.

Bitumina supplies and provides transfer of technology for production of both Anionic & Cationic Bitumen Emulsions in correspondence to ASTM D977-12 and EN 13808-2005. For any inquiries, please contact our sales team on RGE@royalglobalenergy.com

TACK COAT:

Tack coat (also known as bond coat) is a light application of asphalt emulsion between hot mix asphalt layers designed to create a strong adhesive bond without slippage. Heavier applications may be used under porous layers or around patches where it also functions as a seal coat.

Without tack coat the asphalt layers in a road way may separate which reduces the structural integrity of the road and may also allow water to penetrate the structure

The type of emulsion used for tack coats varies from country to country. Normal practice in the USA is to use a slow-setting emulsion that is diluted with water before application. In many European countries cationic rapid setting or specially designated low viscosity medium setting emulsions are used, which are applied undiluted.

PRIME COAT

Prime coats protect the integrity of the granular base during construction and help reduce dust. In the case of a base which is to be covered with a thin hot mix layer or a chip seal for a low volume roadway, priming ensures a good bond between the seal and the underlying surface which otherwise would have a tendency to delaminate.

Compared to cut back asphalt primes, emulsion primes are environmentally friendlier.

Slow-setting grades of asphalt emulsions (diluted with water before application) are suitable. With dense granular bases, or stabilized bases the surface may need to be broken up by scarifying before application, to ensure good penetration.

Bitumen emulsion techniques

Routine repairs, structural maintenance, wearing course maintenance… Bitumen emulsion techniques can meet your needs to maintain the long term serviceability of your pavement. Emulsion techniques are energy-efficient and limit greenhouse gas emissions.

Cold asphalt mixes are made with high quality aggregates and are often used in surface courses as the final road pavement.

The design of cold mixed asphalt concretes usually utilize 0/10mm or 0/14mm aggregate and a selected bitumen emulsion. These types of cold mixes offer the following advantages:

- Low impact on the environment.

- Ease of use (as they are stable and remain workable for several hours).

- Remain flexible over time and are compatible with a wide range of underlying pavement materials.

The performance of bitumen emulsions makes it possible to obtain cold asphalt mixes with a good macro texture, and adhesion characteristics equivalent to those of hot asphalt mix materials.

Due to their qualities, cold asphalt mixes are particularly well suited for:

- Pavements located in difficult climate zones (e.g. mountains, etc.).

- Pavements that are not heavily structured.

- Pavements subjected to low to average traffic (T2 or 300 heavy goods vehicles per day and per lane).

They are best applied with a paving machine/paver, with an average material course thickness between 30 and 50 mm.

Micro surfacing using bitumen emulsion for surface courses

This technique constitutes the thinnest mixture that can be used as a surface course. Micro surfacing is the intermediary between a surface dressing and very thin asphalt concrete.

Micro surfacing protects the underlying pavement by improving impermeability, provides excellent adhesion to the existing road, compensates for small deformations, and has no loose aggregates under traffic.

The use of modified bitumen emulsion provides a good level of adhesion and flexibility over time. The relative simplicity and the speed of laying Micro surfacing minimizes the work time.

The latest technical enhancements with these products guarantees rapid reopening to traffic and significantly reduce the inconvenience for road users.

Micro surfacing is well suited to the maintenance of rural roads, urban roads, highways and airfield runways. In some countries it often constitutes the wearing course on”grave-emulsion”base course surfacing.

Surface Dressing for the renovation of wearing courses

Most importantly, road surfaces must remain impermeable and ensure good adhesion to the existing pavement. Based on these parameters, this surface treatment has always satisfied clients due to its relatively low cost.

The daily outputs are also quite high as the Surface Dressing is rapidly applied. A surface dressing restores skid resistance and seals the road to prevent water ingress.

Surface dressings with bitumen emulsion offer some significant advantages that include: they are not very sensitive to water and to weather conditions, they allow for the spreading of the work over the course of a relatively long season and they overcome the potential problem of moist aggregates.

A variety of surface dressing treatments are available to address the specific problems of each pavement to be treated.

For high traffic or difficult conditions, the modification of the bitumen emulsions by the addition of polymers brings clear improvement to the performances of the surface dressing.

The use of these modified emulsions has become the norm in many countries. A surface dressing with bitumen emulsion is a rapid and economical solution for the renovation of the existing pavements. Its qualities also make it very environmentally-friendly.

“Grave-Emulsion” for pavement resurfacing and reinforcement

Grave-Emulsion

Grave-Emulsion is an asphalt mix obtained from a mixture of aggregate, water and bitumen emulsion which is dosed and mixed cold. This type of treatment offers the following advantages:

- Low impact on the environment

- Ease of use

- An ability to regulate existing pavements and major deformations.

Grave-Emulsion is an ideal product for the resurfacing and reinforcement of low trafficked roads as well as those that are experiencing an increase in traffic.

Grave-Emulsion has been used for more than 40 years on pavements receiving up to 300 trucks per day and per lane. Typical application thickness is around 50mm.

If the aggregates used allow for it, Grave-Emulsion surfaces can be driven on for several months, possibly even several years, before receiving the final wearing course as a step in the progressive development of the road. The final surfacing course is a surface dressing, micro surfacing or a cold asphalt mix.

Recycling of pavements on site using bitumen emulsion

Recycling with emulsion allows for the reconstitution of an improved quality road structure by reusing the existing road materials.

The work is mostly carried out in-situ using specific milling / mixing equipment, this shortens the overall project completion, and limits inconvenience for road users by allowing more rapid reopening of the road to traffic.

On-site recycling follows the principles of sustainable development as:

- Cold recycling saves energy,

- Eliminates the majority of transportation costs as the process minimizes the use of outside materials,

- Minimizes work site waste

This process also offers the following technical advantages:

- It improves the overall homogeneous road structure,

- It improves ride ability of the road

- It treats interface bonding problems,

- It improves impermeability of the road structure

- It conserves the finished pavement levels to minimize further costs

This technique, which has been used in Western Europe and the USA as well as many other countries worldwide for the past 30 years, is now an accepted tool for the road maintenance engineer. Recycling can be carried out on site or in an offsite plant.

Routine repairs of low-traffic roads: surface treatments and emulsion asphalt mixes offer the best solutions

As part of its responsibilities, a road management authority must frequently deal with urgent needs for repairs of sudden and localized degradation problems of the highway network: potholes, deformation of the support, cracking, trenches, etc. These repairs are considered urgent because of the need to protect the safety of users and to preserve the road.

When the degradation does not affect the impermeability of the pavement, the appropriate solution is the application of an emulsion surface treatment. The modest scope of the areas to be treated allows for the use of automatic patching equipment or even manual application. Automatic patching equipment guarantees perfect control of the dosing and the quality of the application.

Where degradations affect the surface course throughout its thickness (e.g. potholes and deformation) the solution to these flaws requires the use of asphalt mixes. Emulsion asphalt mixes are often an excellent solution as they can be stored, they are easy to use, and they are relatively insensitive to climatic conditions. Depending on the thickness of the repair, the cold asphalt mixes can be in the form of 0/6mm to 0/14mm emulsion stabilized aggregates or 0/6mm or 0/10mm cold asphalt mix.

The fact that it can be stored (from several days to several months) makes it suitable for emergency work. Its packaging in buckets also allows for long-term storage. For the topping up or filling of trenches, these emulsion stabilized aggregates or cold asphalt mixes can make up a base course and/or a surface course for temporary and permanent solutions.