Polycarbonate is a dimensionally stable, transparent thermoplastic with a structure that allows for outstanding impact resistance. With high-performance properties, Polycarbonate is the leading plastic material for various applications that demand high functioning temperatures and safety features. Because of its durable make-up, polycarbonate is often the preferred thermoplastic over materials like PMMA and Acrylic. Polycarbonates are unique in its working temperatures and ability to experience minimal degradation between heating and cooling points. Polycarbonate features a high working temperature of 266 degrees Fahrenheit and cooling temperatures at -40 degrees Fahrenheit.

FEATURES OF POLYCARBONATE

- Excellent Impact Resistance

- Minimal degradation between repetitive melting and cooling points

- UV Filtration

- Glare Reduction

- Can be coated with a scratch resistant protection layer

POLYCARBONATE APPLICATIONS

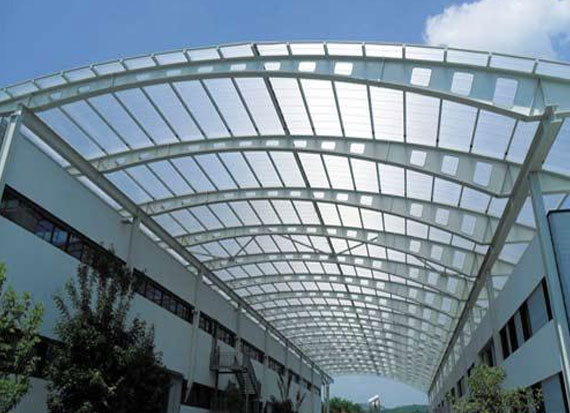

Popular uses of polycarbonate can include aircraft parts, data storage devices, dome lights, eye protection, multiwall sheets, electronic components and more. Due to polycarbonates ability to withstand extreme temperatures for prolonged periods of time, it is often used in components for various industries, including:

- Aircrafts and Aerospace Components

- Greenhouses and Agriculture

- Industrial Lighting

- Electronic Components

- Automotive Components

- Machinery Guards

| Grades | MFR | Application | Typical Application |

|---|---|---|---|

| PGPC0710 Appliances, Lighting, Automotive, sheets & etc. |

7.1-10 | Extrusion/Injection | Packing,Sport,Home |

| PGPC1012 Appliances,Lighting,Automotive,sheets & etc. |

10.1-12 | Extrusion/Injection | Packing, Sport, Home |

| PGPC1215 | 12.1-15 | Injection | Optical,Sports,Electrical,Wire and Cable |

for receiving the full Grade Data Sheet Please contact our customer support team via

sales@futrolpetrochem.com we're happy to support you.