Pavements designed and constructed for heavy-duty traffic and extreme weather conditions require specially designed engineered Bitumen Grades.

By changing the characteristics of normal bitumen with the addition of a polymer, either they are of elastomeric nature or elastomeric, we succeed to obtain bitumen that allows the mixture to be more cohesive, with much more strength and significant higher resistance to parameters like fatigue and permanent deformations for road pavements.

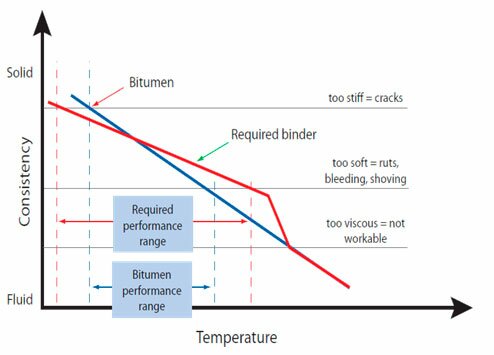

Typical Viscosity of Binder overlooking temperature

- Greater Rigidity

- Better resistance to permanent deformation

- Higher Resistance to spreading cracks

- Greater water resistance

- Much higher durability

Royal Global Energy specializes in the formulation, engineering, production as well as the transfer of technology for production of engineered Polymer Modified Bitumen designed to the specific needs of the respective environment and application of use.

- Very Stressed Pavements

- High Traffic Volume

- High Loading

- High Temperature Amplitude

- More Durable Pavements

- Draining Pavements

The specifications and standards of most countries focus solely on the use of SBS, whereas the use of elastomers, plastomers and other materials are highly beneficial in the design of specific binders. fUTROL has the expertise and knowledge to assist to formulate the best possible binder for the intended application at the best possible price, either with the above solutions or custom design JMF (Job Mix Formulations) with other possible alternatives.

Royal Global Energy can comply with any standard requirements in the country of use, including EN 14023-2012 as well as ASTM D5976-00 and the PG Grading System (e.g. PG 80-10, PG 74-10, PG 70-26, PG 70-28, etc.)